Repair to Blade Shells

Repair of Trailing Edge that goes through both bonded substrates (both bonded shells)

- Remove the topcoat coat around the damage as a first assessment of the damage.

- Cut and grind away all the damaged material until only undamaged glass is visible.

- Cut away the damaged trailing edge and cracked areas.

- Apply hard backing to one side of the blade. (PVC sheet or hard plastic) Prepare with a wax coat or release agent if necessary, to prevent adhesive sticking to the hard back.

- Apply the structural adhesive and reshape the Trailing edge as best as possible.

- The cure time for the adhesive must be fulfilled as specified in data sheets or work instructions. If necessary, use a heating blanket.

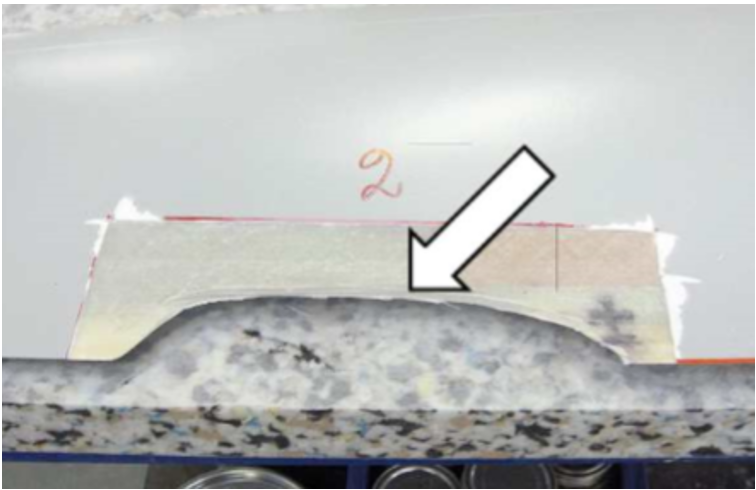

- Once the structural adhesive has fully cured, grind or sand the adhesive to get a smooth and correct profile.

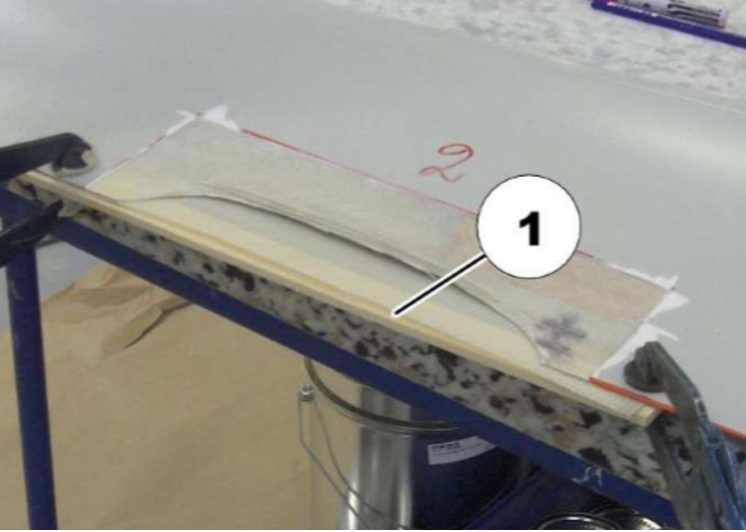

- Create a glass chamfer in preparation for the new fibre layup of the repair.

Use the below measurements as a minimum for replacement layers.

600gsm Biax 30mm Longitudinal > 30mm Traverse

600gsm UD 40mm Longitudinal > 5mm Traverse

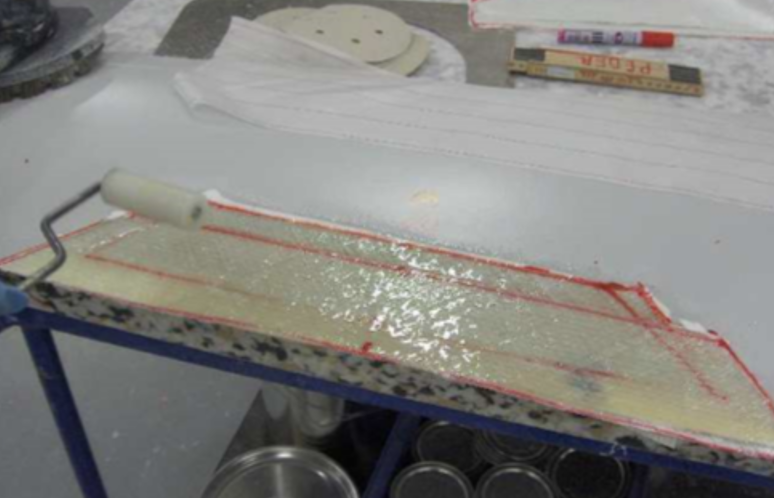

- Select and prepare new fibreglass

- Laminate new layers. Apply peel ply and vacuum consumables if required.

- Once the laminate is cured, prepare the opposite side for lamination.

- Laminate new layers.

- Once cured, grind and sand and prepare for filler and paint coat stages. After the repair, the requirements for TE thickness must be obtained. Refer to any relevant drawings or work instructions for details of thickness requirements.